Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

QDEVU® QDLX133 Screw Press Sludge Dewatering Machine

The sludge dewatering machine is designed to prevent blockages and can clean itself while in operation. It is equipped with a double safe protector to prevent overloading in both mechanical and electrical components, ensuring that it is difficult to break. Additionally, we offer OEM services, allowing you to customize the color and other details to your specific needs.

-

Product Details

QDEVU Screw Press Sludge Dewatering Machine is designed for efficient thickening and dewatering of liquid sludges that emanate from wastewater treatment processes. Typical applications for wastewater treatment plants include dewatering of thickened or unthickened waste activated sludge (WAS), digested sludge from aerobic or anaerobic processes, and dissolved air flotation (DAF) sludges.

The screw press sludge dewatering machine uses the automatic renewal filter cake filtration technology to replace the traditional filter screen filtration to ensure the continuous and stable sludge water separation effect of the dehydrator. Through the strong extrusion pressure generated by the change of screw diameter and pitch, as well as the small gap between the swimming ring and the fixed ring, it realizes the extrusion dehydration of sludge. It is a new type of solid-liquid separation equipment.

WORKING PROCESS

The condtioned sludge flows into the filter chamber from the flocculation tank and is pushed forward the discharging end .With the gap between the thread of the shaft is getting higher and higher.Then the water is separated from the sludge and flows out from the gap between the movings and the fixed rings.The movement of the moving rings the fixed rings cleans the gap between them and prevent the machine from blockage.The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

FEATURE

- Low operation cost:below 40% of belt press.

- Power-saving:less than 5% of centrifuge.

- Water-saving:less than 0.1% of belt filter press

- Saving-drugs:saving around 60%.

- Compact:saving more than 60% of the investment for dehy-dration room.

- Non-clogging:processing the facts & oils and fiber sludge perfectly

ADVANTAGES:

- Application: widely used in municipal sewage, food, beverage, animal husbandry, printing and dyeing, petrochemical, paper, leather, pharmaceutical and other industries

- No blocking: the unique dynamic and static ring filter slot structure makes the equipment not easy to block

- Control: automatic control is adopted, no personnel are required to operate the equipment, and 24-hour continuous unmanned operation is possible

- Operation cost: integrated design, compact structure, greatly saving operation cost; 24-hour full-automatic unmanned operation, greatly reducing labor costs; The equipment covers a small area and reduces the civil engineering investment

- Light and durable: the body is almost entirely made of stainless steel, and the replacement parts are only the screw shaft and the traveling ring, which has a long service life and is durable

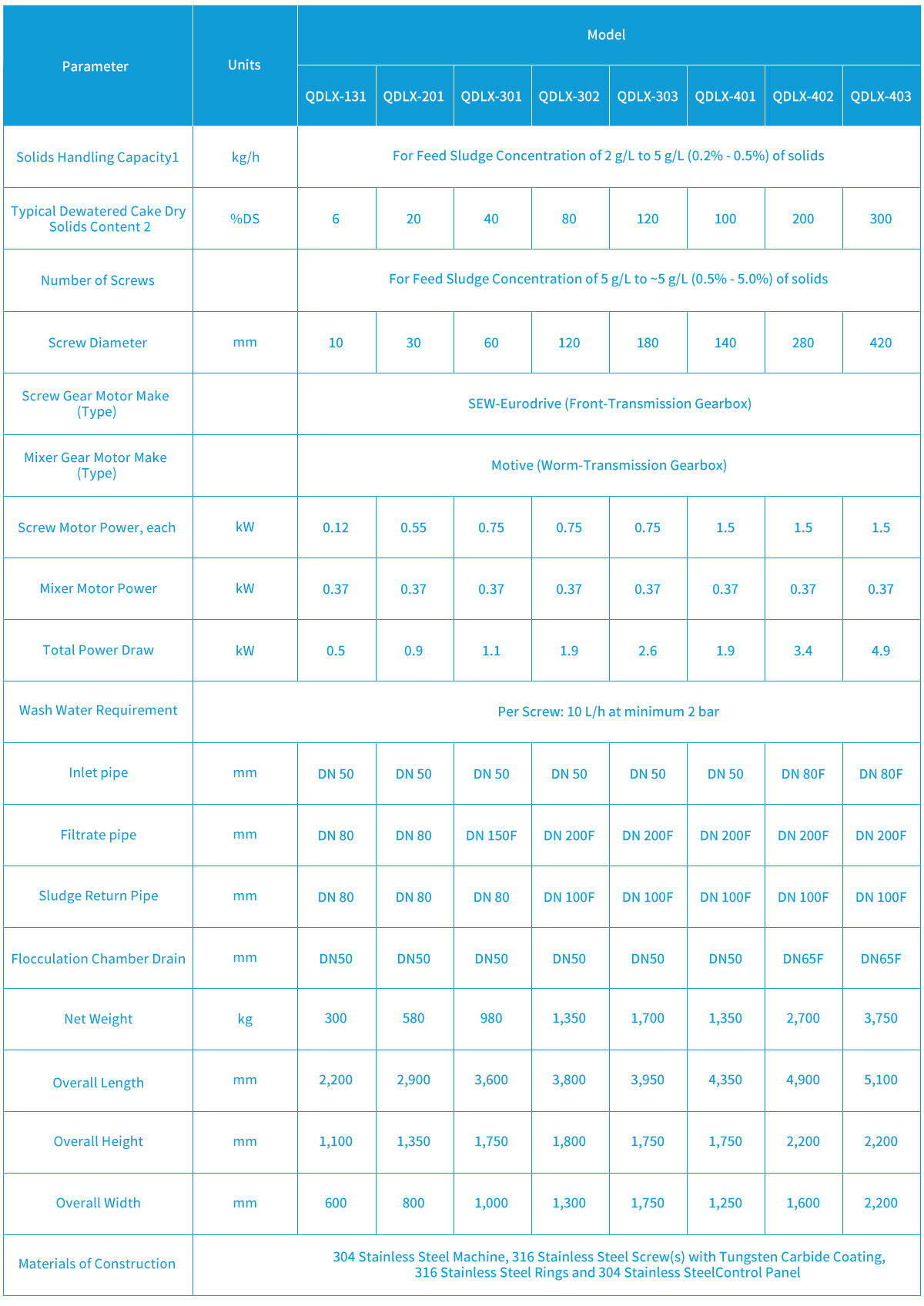

STANDARD SPECIFICATIONS

Notes:

1 Depending on sludge type, polymer type and polymer dose, up to 20% additional throughput may be possible.

2 Depending on sludge type and polymer type, the typical polymer consumption for feed sludge concentration 2 - 5 g/L is 4-8 kg/tonne dry solids processed, and for feed sludge concentration 5 - 50 g/L is 10-25 kg/tonne dry solids processed.

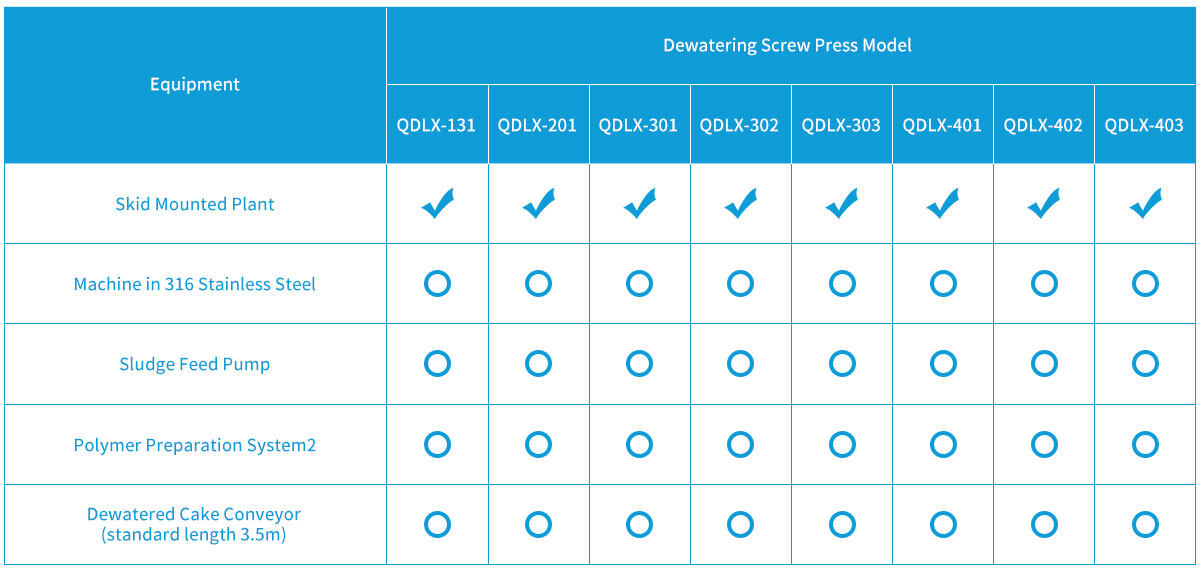

STANDARD INCLUSIONS + OPTIONS

✓= Standard Supply, O = Optional Supply, X = Not Applicable

Disclaimer: QDEVU is continuously updating and improving its products and services, please contact us for more detailed information or to confirm specifications. QDEVU takes no responsibility for any errors resulting from the use of information contained within this document .

CONTACT US FOR MORE DETAILS ABOUT SLUDGE TREATMENT SOLUTION.

If you have specific requirements, contact us about our custom sludge dewatering machine.