Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Food And Beverage Industry Processing Sludge Dewatering Machine

The sludge dewatering machine is an environmentally friendly solution that is widely used in the food and beverage industry for processing. It effectively ensures that the emissions meet national standards. The machine operates silently, and it can be controlled automatically, including self-washing. This makes it a convenient and efficient option for someone looking to reduce their environmental impact.

-

Product Details

QDEVU Screw Press Sludge Dewatering Machine is designed for efficient thickening and dewatering of liquid sludges that emanate from wastewater treatment processes. Typical applications for wastewater treatment plants include dewatering of thickened or unthickened waste activated sludge (WAS), digested sludge from aerobic or anaerobic processes, and dissolved air flotation (DAF) sludges.

The screw press sludge dewatering machine uses the automatic renewal filter cake filtration technology to replace the traditional filter screen filtration to ensure the continuous and stable sludge water separation effect of the dehydrator. Through the strong extrusion pressure generated by the change of screw diameter and pitch, as well as the small gap between the swimming ring and the fixed ring, it realizes the extrusion dehydration of sludge. It is a new type of solid-liquid separation equipment.

FEATURE

QDEVU Screw Press dewatering machine's clog-free feature and can reduce the sedimentation tank and the sludge thickening tank, saving the investment costs of sewage treatment plant construction and water consumption. The main units of MDS are the Screw and Fixed Rings and Moving Rings. Mobilized by the screw, it continuously cleans the sludge out of the gaps, therefore, preventing clogging.

It also can operate automatically controlled by the PLC for 24 hours,unmanned. It's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it costs low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

ADVANTAGES:

- Application: widely used in municipal sewage, food, beverage, animal husbandry, printing and dyeing, petrochemical, paper, leather, pharmaceutical and other industries

- No blocking: the unique dynamic and static ring filter slot structure makes the equipment not easy to block

- Control: automatic control is adopted, no personnel are required to operate the equipment, and 24-hour continuous unmanned operation is possible

- Operation cost: integrated design, compact structure, greatly saving operation cost; 24-hour full-automatic unmanned operation, greatly reducing labor costs; The equipment covers a small area and reduces the civil engineering investment

- Light and durable: the body is almost entirely made of stainless steel, and the replacement parts are only the screw shaft and the traveling ring, which has a long service life and is durable

APPLICATION

- Municipal water and wastewater treatment plants

- Agricultural/fishery community wastewater treatment plants

- Industrial waste treatment plants

- Food/beverage production plants

- Dairy farming/Meat processing plants

- Chemicals manufacturing plants

- Machinery manufacturing/Metal processing plants

- Laundry wastewater

- Other(paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc.)

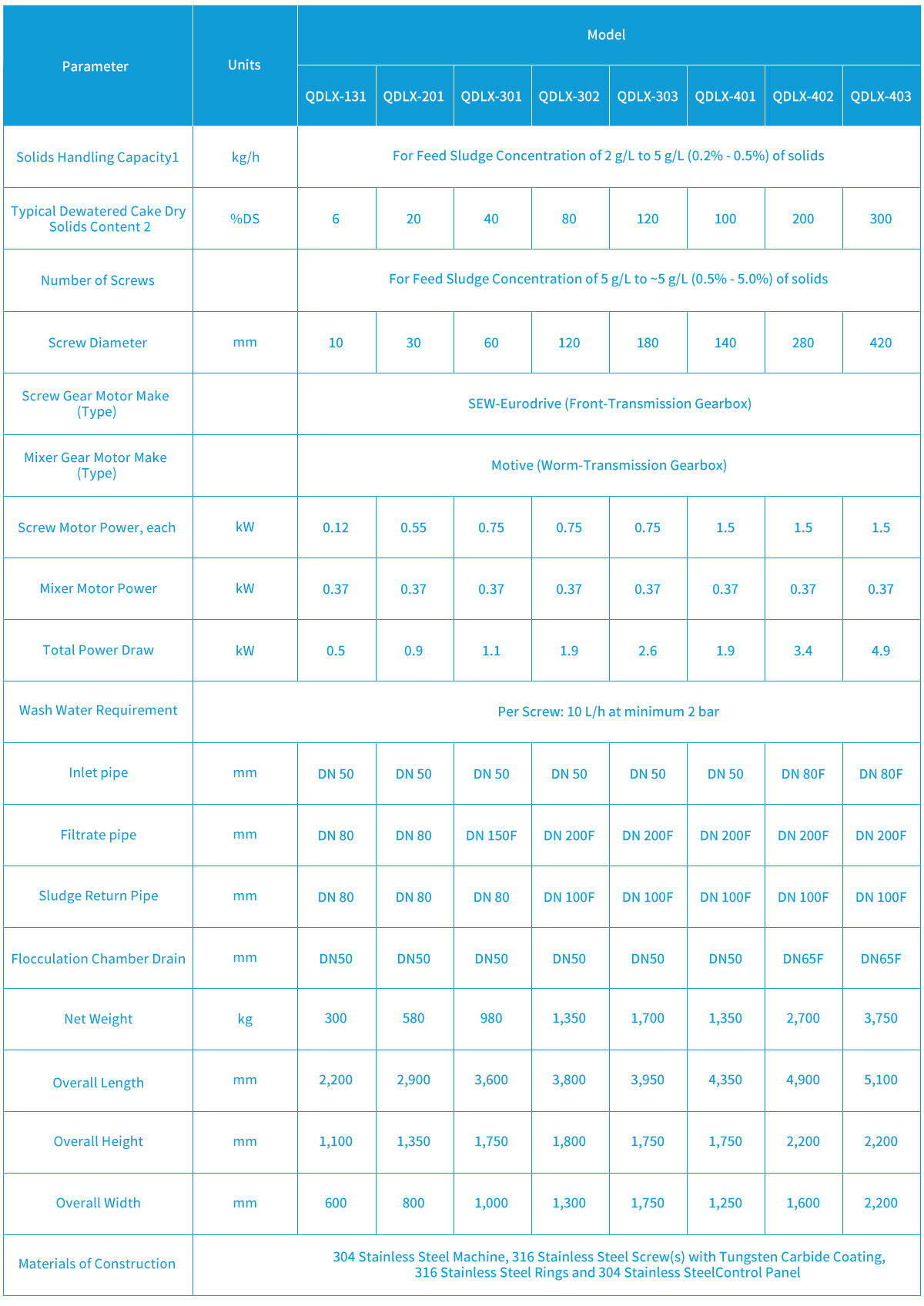

STANDARD SPECIFICATIONS

Notes:

1 Depending on sludge type, polymer type and polymer dose, up to 20% additional throughput may be possible.

2 Depending on sludge type and polymer type, the typical polymer consumption for feed sludge concentration 2 - 5 g/L is 4-8 kg/tonne dry solids processed, and for feed sludge concentration 5 - 50 g/L is 10-25 kg/tonne dry solids processed.

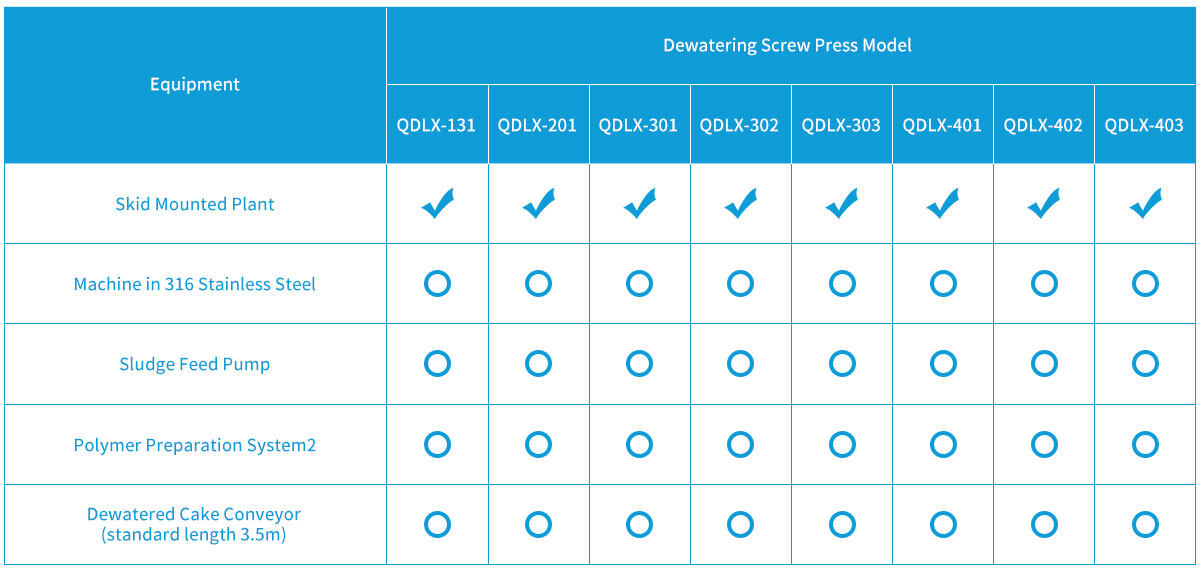

STANDARD INCLUSIONS + OPTIONS

✓= Standard Supply, O = Optional Supply, X = Not Applicable

Disclaimer: QDEVU is continuously updating and improving its products and services, please contact us for more detailed information or to confirm specifications. QDEVU takes no responsibility for any errors resulting from the use of information contained within this document .

CONTACT US FOR MORE DETAILS ABOUT SLUDGE TREATMENT SOLUTION.

If you have specific requirements, contact us about our custom sludge dewatering machine.