Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

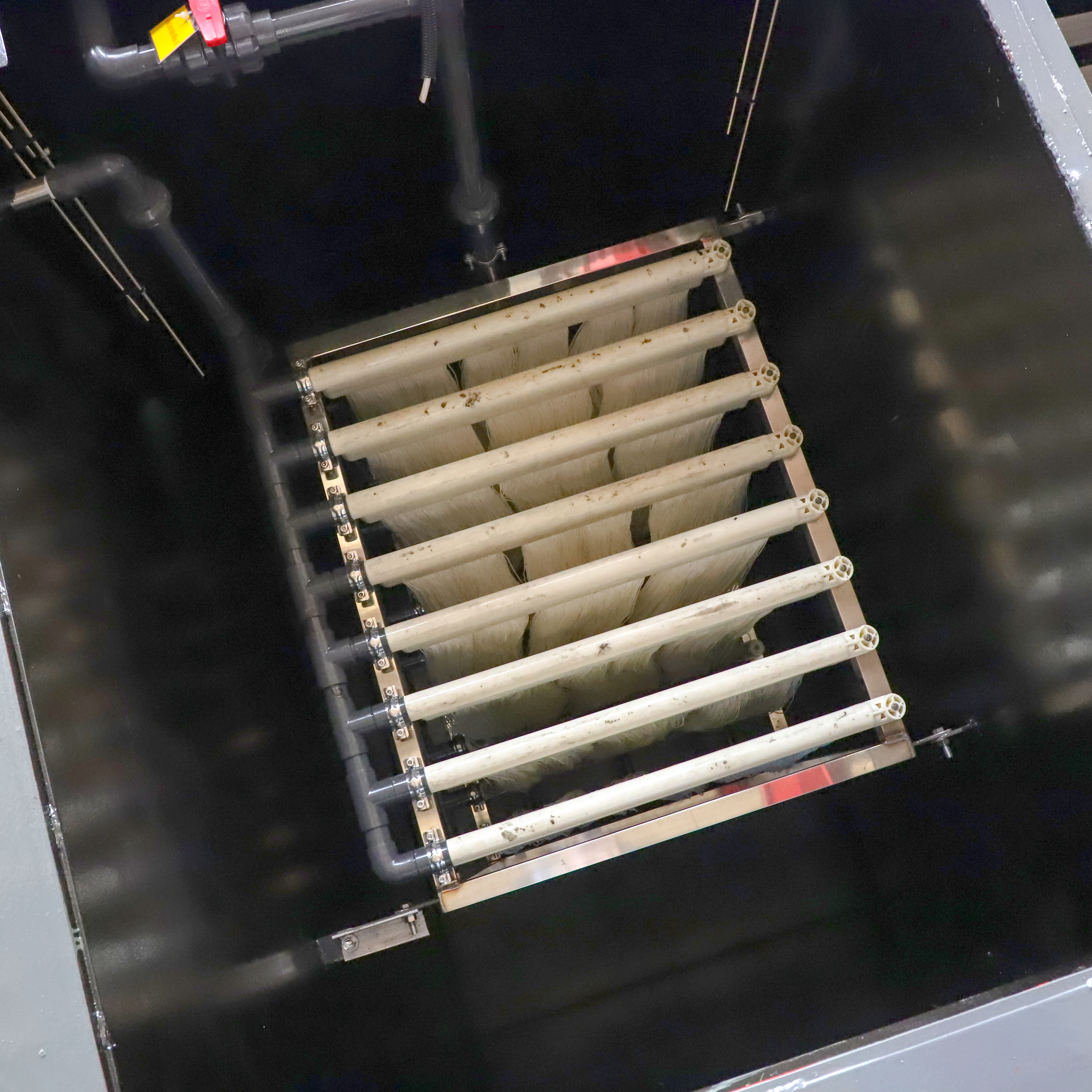

QDEVU® Integrated MBR Sewage Treatment Plant

QDEVU® MBR sewage treatment plant uses advanced biological treatment to effectively clean water, outperforming traditional sewage treatment machines with its efficient and effective separation capabilities. Each component is carefully selected for its high quality, ensuring that replacement parts can be easily found in your country. Additionally, it is versatile and can be used in multiple industries, such as food processing or agriculture.

-

Product Details

QDEVU Integrated Sewage Treatment Plant is mainly for the treatment of domestic sewage and industrial organic wastewater.

QDEVU Membrane Bioreactor (MBR) Integrated Sewage Treatment Plant is designed to treat domestic strength sewage, to achieve “Class A+” treated effluent, suitable for reuse in “risk category high” applications or for discharge to sensitive environments.

MBR, also known as membrane bioreactor, is a new water treatment technology combining activated sludge process and membrane separation technology.The standard treatment process includes influent screening, balance tank mixing, anoxic & aerobic treatment, ultrafiltration (UF) with automated chemical cleaning system, effluent sterilization via UV and/or tank recirculation and residual trim hypochlorite dosing, and analysers for online monitoring of treated effluent turbidity, free chlorine and pH. Additional treatment steps for nutrient removal (T-N & T-P) and sludge de-watering systems may be added as required to suit influent quality and/or treated effluent quality requirements.

QDEVU MBR Bioreactors are constructed of corrosion resistant FRP, and are self-contained, modular systems for easy deployment to remote locations.

FEATURE

Compared with many traditional biological water treatment processes, MBR has the following main characteristics:

- The effluent quality is high and stable.Due to the efficient separation effect of the membrane, the separation effect is far better than that of traditional sedimentation tanks. The treated water is extremely clear, with suspended solids and turbidity close to zero. Bacteria and viruses are largely removed. The water quality of the treated water is superior to the water quality standard for domestic miscellaneous water issued by the Ministry of Construction (CJ25.1-89), and can be directly reused as non drinking municipal miscellaneous water.At the same time, membrane separation also allows microorganisms to be completely intercepted in the bioreactor, enabling the system to maintain a high concentration of microorganisms, which not only improves the overall removal efficiency of pollutants by the reaction device, but also ensures good effluent quality. At the same time, the reactor has a good adaptability to various changes in the influent load (water quality and quantity), withstands impact load, and can stably obtain high-quality effluent quality.

- Less excess sludge output.The process can operate under high volume load and low sludge load, with low excess sludge output (theoretically, zero sludge discharge can be achieved), reducing sludge treatment costs.

- Small floor area, not limited by setting occasions.The bioreactor can maintain a high concentration of microorganisms, the volume load of the treatment unit is high, and the floor area is large and economical; The process flow is simple, compact, and occupies less land. It is not limited by the location. It is suitable for any occasion and can be made into ground, semi underground and underground types.

- Ammonia nitrogen and refractory organics can be removed.The microorganism is completely intercepted in the bioreactor, which is conducive to the interception and growth of slow growing microorganisms such as nitrifying bacteria, and the nitrification efficiency of the system can be improved. At the same time, the hydraulic retention time of some refractory organics in the system can be increased, which is conducive to improving the degradation efficiency of refractory organics.

- Easy operation and management, easy to realize automatic control.This process realizes the complete separation of hydraulic retention time (HRT) and sludge retention time (SRT), and the operation control is more flexible and stable. It is a new technology that is easy to be equipped in sewage treatment, and can realize microcomputer automatic control, thus making the operation management more convenient.

- Easy to transform from traditional process.This process can be used as the advanced treatment unit of traditional sewage treatment process, and has broad application prospects in the field of advanced treatment of urban secondary sewage treatment plant effluent (so as to achieve a large amount of reuse of urban sewage).

APPLICATION

- Urban sewage treatment and building reclaimed water reuse

- Industrial wastewater treatment

- Purification of slightly polluted drinking water

- Fecal sewage treatment

- Landfill/compost leachate treatment

CONTACT US FOR MORE DETAILS ABOUT SEWAGE TREATMENT SOLUTION.

If you have specific requirements, contact us about our custom Integrated Sewage Treatment Plant .