Solid-liquid Separation in Printing and Dyeing Wastewater Treatment Solution

In the previous article, we talked about Printing and Dyeing Wastewater Treatment Solution, today, we will share wastewater treatment methods with you in the printing and dyeing industry.

Wastewater in the printing and dyeing industry

The printing and dyeing industry consumes a large amount of water, with 100~200 tons of water for each ton of textile processed, 80~90% of which is discharged as waste water.

The types of fiber and processing technology of wastewater are different, and the pollutants in printing and dyeing wastewater are also different.

The main methods used for the treatment of printing and dyeing wastewater include Physical method, Biochemical method, Chemical method and several combined treatment methods. In this article, we focus on the physical method and solid-liquid separation.

Physical Method

There are natural precipitation method, adsorption method, etc.

The suspended solids in the printing and dyeing wastewater are mostly organic matters, with a specific gravity similar to that of water. The particle size is generally not more than 10 microns, and the sedimentation rate is very slow. The coarse sediment can be removed by natural sedimentation method, and then the chemical flocculation and sedimentation can be carried out.

The adsorption method is mainly used to treat the dissolved pollutants and decolorize the wastewater. The adsorbents used include activated carbon, activated diatomite, fly ash, etc. At present, granular activated carbon is widely used. Generally, the activated carbon adsorption method should have pre-treatment facilities to remove suspended solids, macromolecular pollutants (such as slurry, surfactant, protein, grease) and other substances in the wastewater, so as to avoid polluting the activated carbon and reducing its adsorption capacity.

1. Fencing method: used to remove floating and suspended substances such as gauze head and cloth block in wastewater. There are mainly grids, grids, screens, etc.

2. Regulating tank: because the water quality and quantity of textile printing and dyeing wastewater vary greatly, a regulating tank must be set. Generally, when the waste water volume is 5000t/d, the retention time of the regulating tank is 4h; When the waste water volume is 2000t/d, the retention time of the regulating tank is 5-6h; When the wastewater volume is less than 1000t/d, the retention time of the regulating tank is 7-8h.

3. Sedimentation tank: the suspended particles of printing and dyeing wastewater are small, so it is not suitable to conduct sedimentation treatment directly without other (such as chemical) pretreatment. The sedimentation tank is divided into horizontal flow type, vertical flow type and radial flow type, of which the former is the most widely used.

4. Filtration method: Most of the filtration methods used in printing and dyeing wastewater are fast filters, that is, under the action of gravity, water passes through the filter at a rate of 6-12 m/h to complete the filtration process.

Solid-liquid Separation in QDEVU

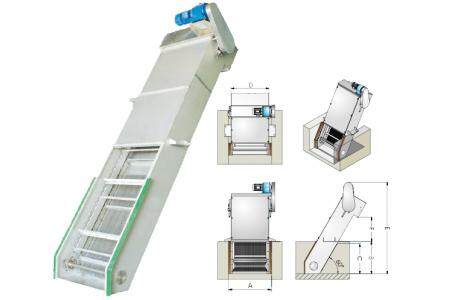

The QDEVU series Mechanical Bar Screen is a device designed to remove debris of varying sizes and shapes from fluid flow to achieve solid-liquid separation.

It is commonly utilized to intercept floating materials and facilitate solid-liquid separation in pump station inlets, urban sewage treatment plants, and industrial wastewater treatment processes. Users can customize operation intervals and schedule periodic operations.

Additionally, the equipment can be automatically controlled based on liquid level differences and also features a manual control function for easy maintenance.

Getting wholesale screen fluid filtration is the perfect solution for printing and dyeing wastewater treatment. Our advanced filtration system removes impurities from printing and dyeing wastewater, ensuring that the water is safe for reuse. Our solution is designed for easy installation and maintenance and is effective at removing particles, chemicals, and other pollutants. Our system is highly efficient, reducing the amount of wastewater produced and conserving resources. With our solution, you can rest assured that the water you use is safe and clean.

#QDEVU #Solid-liquid Separation #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #WATERFILTER #WATERFILTRATION #SLUDGETREATMENT #SLUDGEDEWATERING

Visit www.evuchina.com for more information!