Monosodium Glutamate Processing Wastewater

The Monosodium Glutamate Wastewater mainly comes from the washing water of raw materials and equipment, disinfection waste water, the fermentation mother liquor after extracting monosodium glutamate and the crystallization mother liquor (ion exchange tail liquor) abandoned by concentrated crystallization. Generally, the monosodium glutamate waste water refers to the fermentation mother liquor or ion exchange tail liquor produced in the production process, which is the main pollution source of the monosodium glutamate industry.

The water quality of this kind of wastewater has the characteristics of "five high and one low", that is, high acidity, high COD, high BOD5, high sulfate, high bacterial content and low pH. The residual fermentation bacteria and other organic suspended solids account for about 60% of the total COD, which brings some difficulties to the conventional methods with biological treatment technology as the core.

Process of Wastewater Treatment

IC anaerobic reactor

The determination of the operating conditions of the IC reactor in the treatment of monosodium glutamate wastewater includes the source and amount of bacteria, temperature, pH value, hydraulic retention time, etc. Through the long-term monitoring and analysis of the treatment process of the IC reactor in a monosodium glutamate plant from the commissioning to the full load operation and reaching the standard, the COD removal rate of the IC reactor in the whole operation process is about 60%, which can be seen that the volume load of the IC reactor is high, and the performance of the IC reactor in phosphorus removal is excellent.

Ammonia oxidation (ANAMNOX) process

Compared with the traditional biological nitrogen removal process, this process has obvious advantages: (1) it does not need additional organic matter as an electronic donor, which can save costs and prevent secondary pollution; (2) It can greatly reduce the oxygen consumption and energy consumption; (3) The biological acid production is greatly reduced, and the alkali production is reduced to zero, which can save neutralization reagent.

Determination of the best operating conditions of ammonia oxidation technology in the treatment of monosodium glutamate wastewater, including sludge inoculation, ammonia nitrogen concentration of influent water, pH value, HRT, dissolved oxygen, etc.

Denitrifying filter

There is residual nitrate nitrogen in the sewage treated by the previous treatment process. In order to meet the requirements of emission standards, denitrification filter can be added at the end of the process. The residual nitrate nitrogen in the front end is converted into nitrogen through denitrification and finally removed from the water to realize the complete removal of nitrogen.

There are 12 kinds of typical wastewater sewage water, including:

- Starch Processing Wastewater

- Juice Processing Wastewater

- Hospital Wastewater Sewage Water

- Dairy/Milk Processing Wastewater

- Beer Processing Wastewater

- Papermaking Processing Wastewater

- Slaughtering Wastewater

- Pickle Processing Wastewater

- Monosodium Glutamate Processing Wastewater

- Beverage Processing Wastewater

- Saponin Processing Wastewater

- Community Domestic Sewage Water

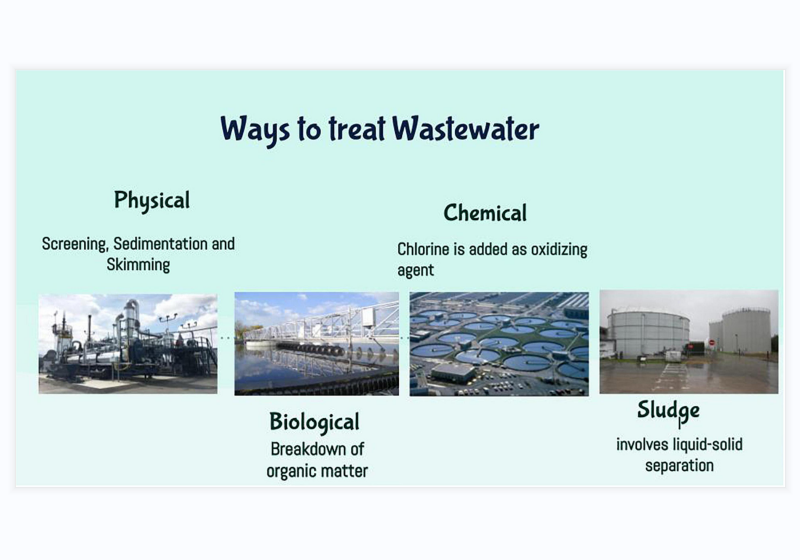

Most monosodium glutamate wastewater treatment technologies are physicochemical and biochemical.The second stage is the key of processing technology.

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #BIOLOGICALTREATMENT #ACTIVEDSLUDGE

Visit www.evuchina.com for more informations!