Hospital Wastewater Sewage Water

There are 12 kinds of typical wastewater sewage water, including:

- Starch Processing Wastewater

- Juice Processing Wastewater

- Hospital Wastewater Sewage Water

- Dairy/Milk Processing Wastewater

- Beer Processing Wastewater

- Papermaking Processing Wastewater

- Slaughtering Wastewater

- Pickle Processing Wastewater

- Monosodium Glutamate Processing Wastewater

- Beverage Processing Wastewater

- Saponin Processing Wastewater

- Community Domestic Sewage Water

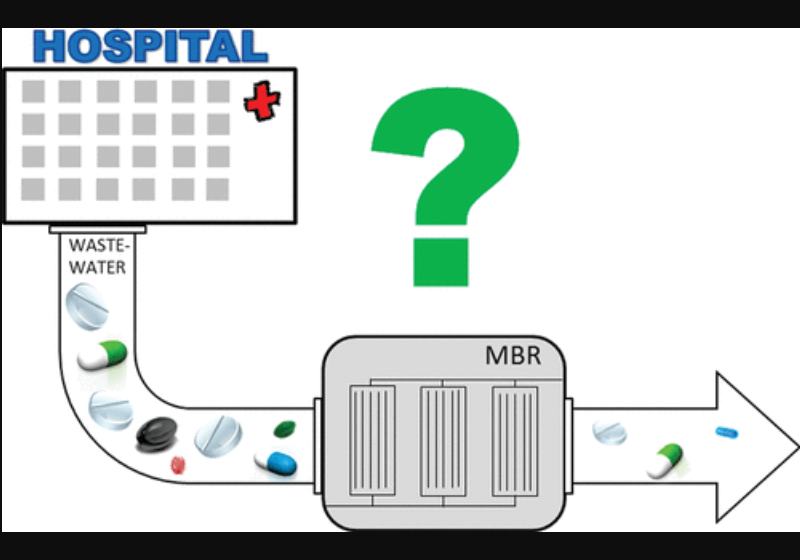

Hospital Wastewater Sewage Water

Source of Wastewater

Hospital wastewater sewage water refers to the diagnosis, treatment, domestic and fecal sewage discharged from the whole hospital park, including medical clinics, wards, operating rooms, various laboratory rooms, pathological anatomy rooms, radiation rooms, laundry rooms, etc. When the drainage of offices, canteens and dormitories is mixed with the above sewage, it is also considered as hospital sewage water.

Features of Wastewater

Hospital sewage contains a variety of bacteria and viruses, and is a gathering place of many pathogens. In the medical system, targeted methods are required for collection and centralized treatment.

Treatment Process Selection of Wastewater

Primary Treatment Processing

The primary treatment system of hospital sewage is divided into Conventional Sewage Water Treatment and Special Sewage Water Treatment. For sewage of special nature, it needs to be collected by category, treated separately after sufficient quantity, and then discharged into the hospital sewage treatment system. Special Sewage Water mainly includes the following types:

- Acid Sewage Water. Neutralization method is adopted for treatment. The neutralizer can be sodium hydroxide, lime, etc., and neutralized to pH 7~8.

- Cyanide-containing Sewage Water. Alkaline chlorination method is used for treatment.

- Mercury Containing Sewage Water. The method of sodium sulfide precipitation+activated carbon adsorption should be adopted for mercury-containing wastewater. After being adsorbed by activated carbon, the mercury concentration in the effluent can meet the relevant discharge standards before entering the hospital sewage treatment system.

- Chromium-Containing Sewage Water. Chemical reduction precipitation method is adopted for treatment.

- Radioactive Sewage Water. Radioactive sewage discharged from isotope therapy should be collected separately and can be directly discharged into the decay pool. Special attention should be paid to the anti-seepage and anti-corrosion of the decay pool.

Secondary Treatment Processing

Membrane Bioreactor Process(MBR)

Sequencing Batch Reactor Process(SBR)

SBR method can be used according to influent water quality, intermittent influent water, strong mixing, single reaction tank reaction and static sedimentation.

The advantages of this treatment method are: the facilities are relatively simple, which has important reference significance for hospitals that need to transform the sewage treatment system; It can be controlled automatically without sludge backflow operation, reducing labor intensity; Strong adaptability to places with fluctuation of sewage flow; The sludge has high activity and fast sedimentation, and has good inhibition on the growth of filamentous bacteria and sludge bulking.

Different disinfection methods should be used to kill pathogenic microorganisms and fecal coliforms at the initial or final stage.

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #BIOLOGICALTREATMENT #ACTIVEDSLUDGE

Visit www.evuchina.com for more informations!