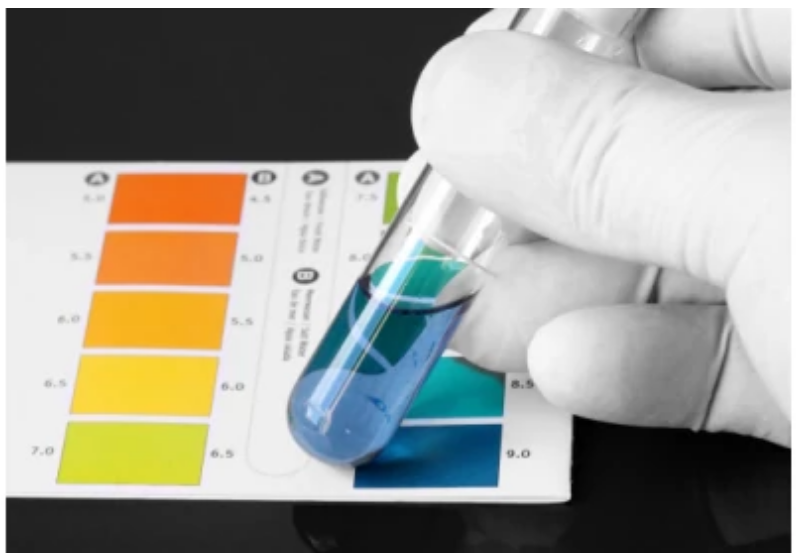

Acid Alkali Wastewater Treatment

Acid alkali wastewater is the most common type of wastewater treatment.

- Acidic Wastewater mainly comes from steel plants, chemical plants, dye plants, electroplating plants, and mines. Wastewater treatment should focus on treating wastewater containing various harmful substances or heavy metal salts.

- Alkaline Wastewater mainly comes from printing and dyeing factories, leather factories, paper mills, refineries, etc. When treating wastewater, organic or inorganic alkalis may be encountered.

- Acid and alkali wastewater, in addition to containing acid and alkali, often contains acid salt, alkali salt and other inorganic compound and organic matter.

Acid alkali wastewater has strong corrosiveness and can only be discharged after appropriate wastewater treatment.Low concentration acid-base wastewater, such as the cleaning water of the acid washing tank and the rinsing water of the alkali washing tank, should be treated with neutralization wastewater.

For neutralization treatment, the principle of treating wastewater with waste should be considered first. If acid and alkali wastewater neutralize each other or use waste alkali (slag) to neutralize acidic wastewater, use waste acid to neutralize alkaline wastewater. In the absence of these conditions, neutralizers can be used for wastewater treatment.

Self Neutralization Method

Neutralize the waste acid generated by the regeneration of cation exchange agents to neutralize the waste alkali generated by the regeneration of anion exchange agents, in order to achieve the goal of neutralization.

- Single tank type: The waste acid and alkali solution are directly discharged into a mixing tank, and after stirring evenly, they are discharged;

- Double tank type: Set up a waste alkali tank and a mixing tank at the same time. The waste alkali liquid is discharged into the waste alkali tank for storage. When the cation exchanger is regenerated, the waste acid and waste alkali liquid are discharged into the mixing tank for neutralization and then discharged;

- Three tank type: simultaneously set up one waste alkali tank, one waste acid tank, and one mixing tank.

The disadvantage of self neutralization method is that the amount of waste acid and alkali discharged from power plants is unbalanced and cannot be precisely neutralized, resulting in the treated water quality not meeting the discharge standards. Therefore, it is often necessary to add some acid or alkali.

Dosing Neutralization Method

- Add alkaline agents such as lime (CaO), limestone (CaCO3), carbide slag, caustic soda (NaOH), sodium carbonate (Na2CO3), etc. to acidic wastewater.

- Add acidic agents such as hydrochloric acid (HCl), sulfuric acid (H2SO4), etc. to alkaline wastewater to achieve the goal of neutralization.

The equipment for neutralization reaction can be divided into neutralization tank and neutralization tower.

Neutralization tanks are generally arranged above or underground. Acid and alkali wastewater enters the tank through channels or pipelines with a height difference, and the treated wastewater is discharged by pumps.

The advantage of neutralization tank is that the system is simple and easy to operate.

The disadvantage is that it occupies a large area and is difficult to prevent corrosion and seepage.

Neutralization tower is set at a certain height above the ground, and the acid and alkali wastewater is piped to the upper part of the neutralization tower. A circulating pump is used to evenly mix the acid and alkali in the tower, and the treated wastewater is discharged by the level difference.

The advantages are that the anti-corrosion of the tower body is easy to do, there is no leakage problem, and the floor area is small; Its disadvantage is that the pressure of the ion exchanger regeneration pump is required to be correspondingly increased, so that the drainage can directly enter the top of the neutralization tower. Therefore, the compressive strength and uniformity of ion exchange resins are correspondingly required to be improved.

Visit www.evuchina.com for more informations!

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #WATERFILTER #WATERFILTRATION #SLUDGETREATMENT #SLUDGEDEWATERING